Why Polishing Nails Before Galvanizing or Welding?

Many nail manufacturers have such questions:

“Is nail polishing really necessary?”

“We can still galvanize and weld nails without polishing — so why spend more money?”

Nail polishing is not an optional “decorative process” but a key step that affects the galvanizing effect and welding quality of nails. Especially for manufacturers who do export and coil nail welding, this step can even determine your customer satisfaction and return rate.

What is Nail Polishing? What is It Used for?

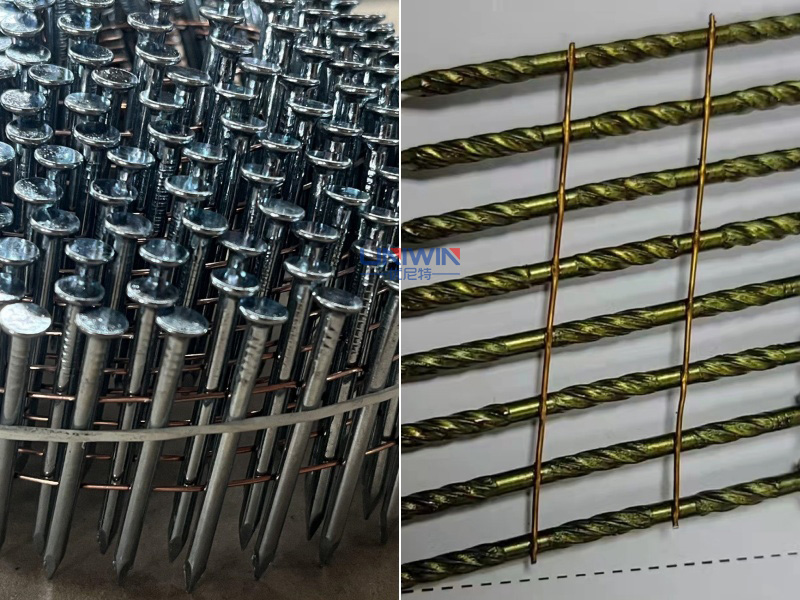

Nail polishing is the mechanical process of removing burrs, rust, and oxidation from the surface of metal nails for smooth galvanizing and coil nail welding. Through a nail polishing machine, the nails are tumbled with sawdust, paraffin or waste engine oil to make the nail surface clean, smooth and bright.

To put it simply, it is to clean and polish the nails to prepare for galvanizing and welding.

What Problems are Likely to Occur with the Galvanizing of Unpolished Nails?

Poor Adhesion of Zinc Layer

If there is rust or oil on the nail surface, the zinc layer cannot be attached at all, and quality problems such as “layer shedding” and “blackening” are likely to occur.

Uneven Galvanizing and Poor Appearance

The customer received nails with different colors and mottled edges, which gave a bad first impression and made it difficult for the export to pass the inspection.

What Will Happen If the Unpolished Nails Are Used for Coil Nail Welding?

Poor Welding

Especially when using copper-plated welding wire, if there are rust or burrs on the nail rod, it will affect the arc connection, the welding point will be unstable, and the nails will fall off during transportation.

Frequent Nail Jams

The machine is easy to jam and misalign when feeding, resulting in frequent shutdowns, wasting labor and reducing production capacity.

Uniwin Nail Polishing Equipment Recommendation

Looking for a durable, efficient, and easy-to-use polishing solution?

The Uniwin Nail Polishing Machine is for nail factories aiming for superior surface quality, stable welding, and consistent galvanizing results.

- Wide Nail Compatibility: Suitable for ordinary iron nails, concrete nails, screw nails, coil nails, etc.

- Flexible Capacity Options: Available in 400kg, 600kg, and 1000kg models.

- Simple & Automatic Operation: Just load the nails and polishing media, press start, and the machine will run automatically.

- Outstanding Polishing Results: Fast rust removal, smooth finish, minimal dust — perfect for export standards.