Nail Production Line

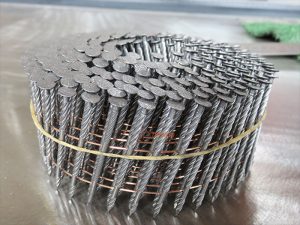

Nail production Lines For wire nails/coil nails/roofing nails/concerete nails/screw nails

This section mainly writes about different nail production lines, including wire nail making machine, coil nail making machine, umbrella head roofing nail making machine, clout nail making machine, concrete nail making machine and screw nail making machine.

The nail production line refers to the machine making line to manufacture wire nails, coil nails, roofing nails, clout nails, concrete nails and screw nails with a series of machines. This process involves several stages and a series of machines to transform steel wire into finished nails and meets the mass production of nails. This is a simplified explanation, but the actual process can be more complex and varies depending on the specific type of nails being produced, the technique being used, and the particular practices of the manufacturer. And modern nail production lines are often highly automated, with machines handling most of the work.

FAQ

We have customers from over 50 countreis over the world, for example:

North America: Canada, United States, Mexico.

South America: Brazil, Argentina, Peru.

Europe: Germany, Sweden, Poland, Greece, Belgium, Russia, Spain.

Middle East: Saudi Arabia, UAE, Iran, Qatar, Turkey.

Africa: Kenya, Ghana, Congo, Egypt, Ethiopia, Zambia South Africa, Morocco, Rwanda, Uganda, Tanzania

The raw material for wire nail making is Q195/SAE1008 low-carbon steel wire, and this model is widely used worldwide in every nail making plant.

- Different appearance. Wire nails are generally tapered heads and smooth shanks, but coil nails are generally flat heads and three types of shanks, including smooth, ring and screw shaft.

- Different installation methods and applications. Wire Nails are typically driven into the workpiece by a hammer, mostly used for rough carpentry or heavy-duty woodwork, and the efficiency is low. Coil Nails are typically driven into the workpiece by a pneumatic nail gun, which can greatly increase efficiency. In a minute, the nail gun can punch 60 pcs nails into wood, however, the hammer can only punch max 2 or 3 nails.

- Different production machines. Wire nails are produced by the wire nail making machine, and coil nails are manufactured by the thread rolling machine and coil nail making machine.

No, you need at least three models to make 1-6 inch nails, i.e., you need one Z94-2C to make 1-2 inch nails, one Z94-4C to make 2-4 inch nails, and one Z94- 5C to make 4-6 inch nails.

Generally, 3-4 workers are enough for a small nail factory.

For wire drawing machines, 1 worker,

For nail making machines, 1 worker,

For packaging the nails etc., 1 worker.

For one skilled nail machine operator, one operator can operate 5-10 sets nail making machines at the same time.

We offer several kinds of payment, such as TT, LC, Western Union, and Paypal.

However, the general payment terms are 30% deposit by TT, and the 70% balance by TT before delivery or against the copy of BL. After the machine production is finished, we will send photos and testing videos to our customers.