What is barbed wire making machine?

The barbed wire making machine is a piece of equipment that automatically produces barbed wire, a type of barbed wire fencing with sharp edges or points used to build agricultural fences and other barriers. A barbed wire machine usually includes an unwinding device, a wire feeding system, a twisting device, a barb system, a tightening and winding device, a control panel, and a motor. The uniwin brand barbed wire machine can produce single or double-strand wire to meet different fencing needs.

High speed barbed wire machine can produce over 600 feet of barbed wire per minute. Our factory mainly has the single strand barbed wire machine, razor blade barbed wire machine and double strand barbed wire machine, and double strand barbed machine includes normal twist barbed wire machine and normal and reverse twist barbed wire machine.

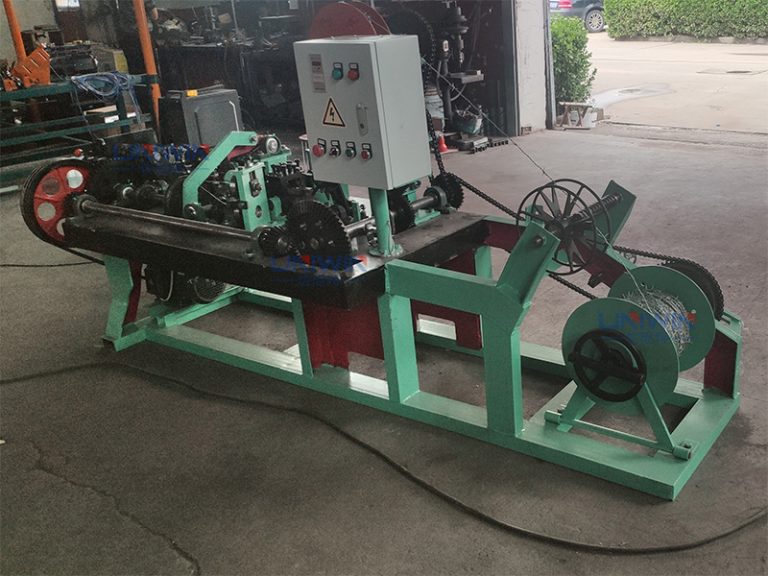

Single strand barbed wire making machine

The single strand barbed wire making machine uses only one main wire to produce barbed wire, with barbs wrapped around the wire at regular intervals. The single strand barbed wire machine comprises two parts: wire winding and wire collecting. It is equipped with three wire reels and adopts advanced electronic counting control. The machine operates smoothly and has low noise, high production safety, low energy consumption, and high production efficiency.

Finished product

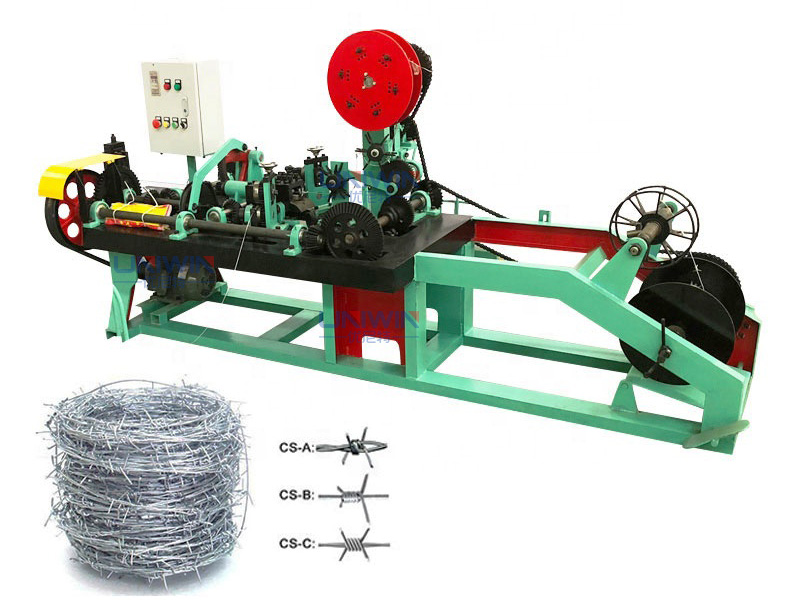

Double strand barbed wire making machine

The double strand barbed wire making machine produces stronger barbed wire by twisting two strands of wire together and twisting the barbs at regular intervals between the two wires. The machine consists of two parts – wire winding and wire collecting and twisting and is equipped with four wire reels. This machine can produce double strand positive twist barbed wire and positive and negative twist barbed wire without rebound or twisting, and these two types of barbed wires are widely used in national defense, railways, highways, agriculture, animal husbandry, and other industries. The machine works coordinated, moves smoothly, and has slight vibration and no torque. It also uses advanced electronic counting control, which can set the production weight at will and stop until it reaches the required weight.

Finished products

Normal twist barbed wire is popular in Middle East, South Africa, etc.

Normal and reverse twist barbed wire is popular in Middle East, Kenya, America, etc.

IOWA barbed wire vs. GLIDDEN barbed wire

“IOWA” and “GLIDDEN” refer to specific types of double strand barbed wire. The barbs of GLIDDEN barbed wire are twisted around two main wires, while the barbs of IOWA barbed wire are only on one main wire.

Barbed wire making machine features

- Thickened body. The machine is made of thickened materials and has a solid structure and high-quality components, which can extend the machine’s service life and resist wear and corrosion.

- Production monitoring. The control panel display tracks operating speed, productivity, failures, and other metrics to optimize throughput.

- Automatic stop. The machine is equipped with sensors that trigger an automatic stop if there is a problem, such as a broken line, to prevent waste and ensure operator safety.

- Easy to maintain. Modular components with quick-access panels enable routine maintenance and parts replacement, reducing downtime and extending usage.

- High speed production. Barbed wire machines can produce 600-1,000 feet of continuous barbed wire per minute, enabling efficient mass production.

- Automated operation. Programmable controllers automate wire feeding, barbing, twisting, and winding with precision and consistency.

- Barb spacing adjustment. The machine often adjusts the spacing between barbs, allowing the user to customize the wire to specific needs.

Barbed wire making machine parameters

| No. | Item | Parameter |

|---|---|---|

| 1 | Electric Motor | 3 kw |

| 2 | Production Capacity | 80-120 kg/h |

| 3 | Barbed Pitch Space | 3-5 inch |

| 4 | Barbed Wire Diameter | 1.6-2.5 mm |

| 5 | Main Drive Shaft Speed | 402 r/min |

| 6 | Barbed Wire Winding Speed | 470 r/min |

| 7 | Wire Pulling Speed | 134 r/min |

| 8 | Main Machine Size | 1900X1300X980 mm |

| 9 | Machine Weight | 1100 kg |

Raw materials for barbed wire production

The raw materials for barbed wire can be hot-dipped or electro-galvanized, PVC-coated wire AISI430 and AISI304, Stainless Steel wire, low carbon steel wire, High-Tensile Wire, aluminum wire, etc.

Application of barbed wire

Due to its economy, durability and deterrent effect, barbed wire is widely used for protection and fencing in national defense, prisons, railways, highways, wildlife reserves, sports facilities, construction sites, historical sites, agriculture and animal husbandry, residential buildings, etc. However, care should be taken when using it, especially in areas with a risk of harm to humans or animals.

Barbed wire making machine price

The barbed wire making machine price may vary based on their production capabilities, features and automation, brand and manufacturer, buyer geography, market dynamics, machine size, customization and accessories, etc. Our factory’s barbed wire machine price ranges from USD 5,000 to 6,500 per set.