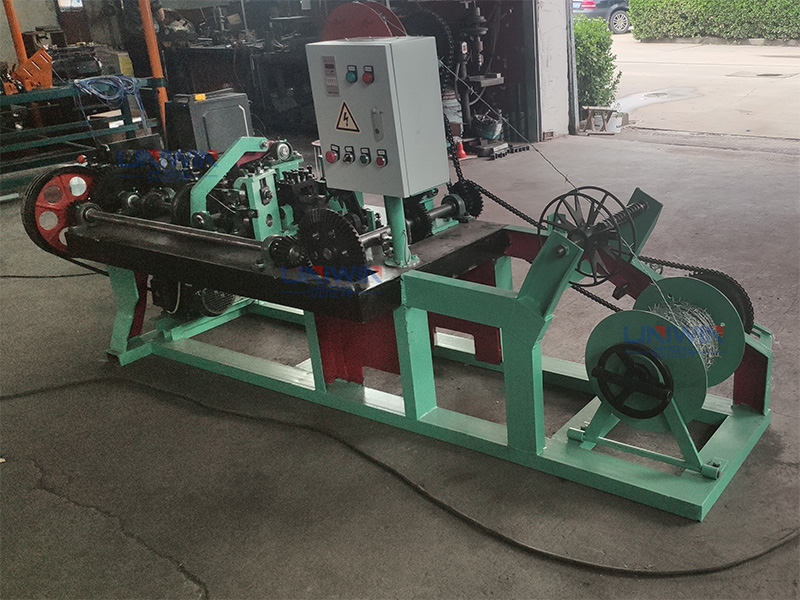

Pulley Type Wire Drawing Machine – Factory Price & Reliable Supplier

Uniwin specializes in pulley type wire drawing machines, widely used in nail wire, steel wire, and iron wire processing. Compared with straight line or water tank models, pulley type machines are more cost-effective and easier to maintain, making them the ideal choice for medium-scale factories and nail manufacturers.

All machines are CE certified, offered at factory-direct prices, with worldwide delivery and reliable technical support.

What is Pulley Type Wire Drawing Machine?

The pulley type wire drawing machine is an automatic device used to reduce the diameter of metal wire by pulling it through a series of drawing dies with decreasing sizes. It is commonly applied in nail wire, binding wire, and low-carbon steel wire production, ensuring smooth surface finish and consistent wire quality.

Advantages of Pulley Type Wire Drawing Machine for Nail Making

- High Efficiency – continuous production with minimal supervision.

- Accurate Wire Size – precise diameter control using high-quality dies.

- Cost-Effective – lower investment, reduced labor and material waste.

- Easy to Operate – simple design, fewer workers needed.

- Versatile Use – suitable for different wire materials such as nail wire, binding wire, and low-carbon steel wire.

Applications of Multi-Drum Wire Drawing Equipment

Nail Making (Wire Nails, Concrete Nails…)

Steel Wire for Construction

Binding Wire And Iron Wire Processing

…

Pulley type machines are especially recommended as wire drawing machine for nail making due to their stable performance and affordable cost.

Dry Pulley Type Drawing Machine Parameter

| No. | Item | Parameter |

|---|---|---|

| 1 | Motor | 15kw/drum |

| 2 | Drum Size | 550mm |

| 3 | Drum Speed | 55-70rpm |

| 4 | Max Wire Diameter | 7/8mm |

| 5 | Output | 500-800kg/h |

| 6 | Machine Weight | 3T (3 Drums Type) |

Components of Pulley Wire Drawing Machine

A wire drawing machinery is made up of several key components:

Wire Reel – holds the original wire coil and feeds it to the wire machine.

Wire Drawing Die – reduces wire diameter, usually made of tungsten carbide.

Capstan (Drum) – pulls the wire through the die at a continuous speed.

Drawing Die Box – holds dies and drawing powder.

Drawing Powder – reduces friction between wire and drawing dies and extends drawing die life.

Auxiliary Equipment for Dry Pulley Wire Drawing Machine

To ensure smooth production, the pulley type wire machine is often used with auxiliary devices:

Sharpening Mill: presses and tapers the wire head to pass through the first die easily.

Butt Welding Machine: connects broken wires for continuous production.

Pulley Type Wire Drawing Machine Price Guide

The price of a pulley type wire drawing equipment depends on the number of drums and output capacity:

1 Drum: USD 2,000 – 4,000

2 Drums: USD 4,000 – 8,000

3 Drums: USD 6,000 – 12,000

…

Uniwin offers factory-direct prices, CE certification, worldwide delivery, and technical support. Contact us for a customized quotation!

About Uniwin – Wire Drawing Machine Manufacturer

As one of China’s most professional wire drawing machine manufacturers, Uniwin has exported machines to over 30 countries, including Kenya, Uganda, Ghana, Saudi Arabia, Turkey, America, and Brazil, etc. We focus on equipment quality and offer installation guidance, technical support, and professional after-sales service for customers who buy wire drawing equipment.