Complete Production Process of Copper-Coated Welding Wire for Coil Nails

Copper-coated welding wire plays a key role in coil nail welding, ensuring strong and clean welds in high-speed automatic coil nail production lines. The coil nail welding wire is a key component in coil nail making equipment, enabling consistent weld performance and corrosion resistance.

In this article, we’ll explore the full coil nail welding wire production process.

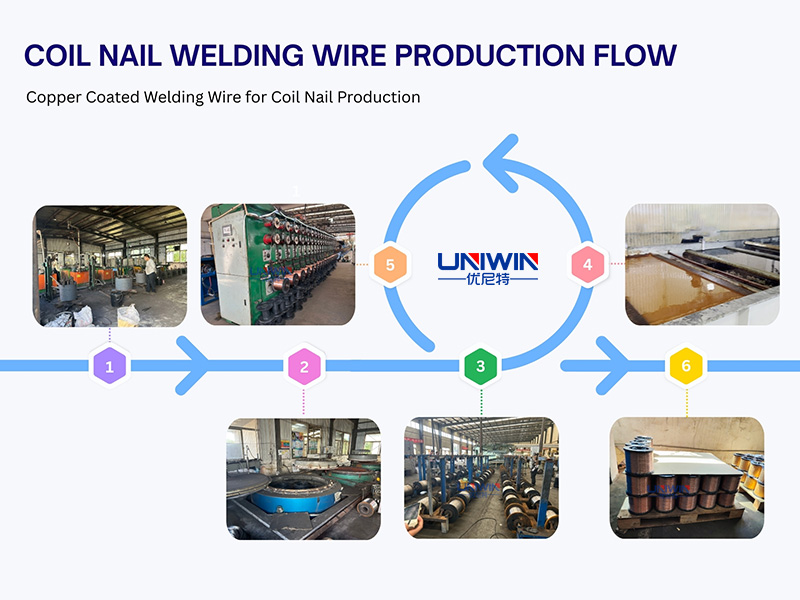

Coil Nail Welding Wire Manufacturing Process

Below is the manufacturing sequence for copper-coated welding wire used in coil nail production:

Wire Drawing → Annealing → Wire Pay-Off → Cleaning → Pickling → Cleaning → Copper Coating → Final Cleaning → Drying → Wire Take-Up

Welding Wire Process Steps Explained:

- Wire Drawing: Steel wire is drawn to the required diameter for coil nail welding using a wire drawing machine.

- Annealing: The drawn wire is heat-treated to relieve internal stress and increase flexibility.

- Wire Pay-Off: The annealed wire is smoothly fed into the surface treatment line.

- Initial Cleaning: Removes surface contaminants, such as rust, oil, and dust.

- Pickling: Acid treatment removes oxidation and prepares the surface for plating.

- Cleaning: Neutralizes and cleans residual acid to prevent corrosion and prepare for coating.

- Copper Coating (Electroplating): A uniform copper layer is electroplated onto the wire to improve welding performance and conductivity.

- Final Cleaning: Cleans off the remaining plating solution for a clean wire surface.

- Drying: Removes moisture to prevent rust or oxidation before packaging.

- Wire Take-Up: Finished wire is rewound into coils for easy handling.

Packaging Options for Welding Wire

Proper packaging of coil nail welding wire helps maintain quality during transportation and improves feeding in automatic coil nail machines. We offer two packaging options for copper-coated welding wire:

- Spool Type (I-shaped reel)

- Drum Type (Barrel packaging)

Why Use Copper-Coated Coil Nail Welding Wire?

Enhanced welding stability and quality

Prevents oxidation and rust during storage and use

Smooth wire feeding and welding in coil nail welding

💡 Get Expert Help

Need high-quality welding wire or nail making equipment for your coil nail production line? Contact us for technical support and a competitive quotation.