What is the wire nail production line?

The wire nail production line is an industrial setup designed to produce wire nails. This process involves several stages and different types of machinery to transform steel wire into finished nails and meets the mass production of wire nails. Wire nails, also called common nails, are the backbone of many construction and manufacturing projects. Because of their good corrosion resistance, long service life, fast nailing speed, and simple operation, wire nails are very popular in the application of furniture, construction, home decoration and woodwork.

How to make wire nails?

There are mainly three machines involved in the production of wire nails, which are wire drawing machine, nail making machine and polishing machine. The wire drawing machine uses different drawing dies to reduce the diameter of steel wire to the desired size. The nail making machine cuts the wire into lengths, makes the nail head, and sharpens the point. The nail polishing machine adds saw dust to make nails smooth and bright.

The Wire Nail Manufacturing Process

The production process of high-quality wire nails includes wire drawing, wire nail making, nail polishing, quality inspection and packaging.

Wire drawing

This is the first step where the raw material steel wire Q195 or Q235 of diameter 6.5 mm is drawn by the wire drawing machine into small diameter wire like 2.5mm, 3.5 mm, 3.7 mm and 4.5mm. Sharpening mill, drawing powder and butt welding machine play an important role in the drawing process. The steel wire passes through the drawing powder and later enters the drawing die, which can reduce the friction between the steel wire and the drawing die and prolong the service life of the drawing die.

Wire nail making

The drawn wire is then fed into the wire nail making machine, which cuts the steel wire into nails and makes nail heads. Different sizes of nails can be made by adjusting the machine. The working principle of the wire nail making machine includes four processes. First, put the drawn wire rod on a wire reel and feed steel wire to the wire nail making machine. Second, when the nail mold grips the steel wire, the pin punch begins to make the nail head. Next, the feeding box sends the steel wire forward. Finally, the nail cutter cuts the nail according to the set length and cuts the nail point, and then wire nails fall from the machine outlet into the collection box.

Nail polishing

The nails from the nail making machine have sharp edges and may have some residual oil or grease. The nail polishing machine is to polish wire nails with saw dust, engine oil, paraffin or other materials, ensuring they are clean and free of burrs. Saw dust is to remove any sharp edges, engine oil is used to brighten wire nails and give a shiny surface, and paraffin is to increase the rust resistance of wire nails.

Quality Inspection

After polishing, the nails undergo quality inspection. This can involve both manual and machine inspection to ensure the nails meet the desired specifications.

Packaging

Once the nails pass the quality inspection, they are packaged in cartons. Different cartons fill different sizes and weights of nails, such as 1kg, 5kg, 20kg or 25kg per carton.

It’s important to note that different manufacturers may have slightly different processes. However, the basic principles remain the same.

Auxiliary Equipments in the Production of Wire Nails

In addition to the three main equipments, the auxiliary devices mentioned below also play a significant role.

- Sharpening mill. The sharpening mill is to grind the raw material steel wire tip finely before passing it into the wire drawing machine.

- Butt welding machine. The butt welding machine ensures the continuous operation of the wire drawing machine. If the wire breaks during the wire drawing process, we need to use the butt welding machine to weld the two ends back together.

- Nail cutter grinder. The nail cutter grinder’s function is to grinder the nail cutter when it becomes blunt and make the cutter sharp again.

The Quick-Wear Parts in Producing Wire Nails

Wire nail production is a high-speed, high-intensity process that stresses machinery considerably. This causes some parts of the machinery to wear out faster. To keep the production line running smoothly, we need to inspect, maintain and replace these parts regularly. The following are the most common wearing parts on the wire nail production line:

- Wire drawing die. The wire drawing die is used to reduce the steel wire to the needed diameter. In the wire drawing machine, due to the friction between the steel wire and the dies, these dies wear out relatively quickly and need to be replaced regularly. Every wire drawing die can produce up to 20 tons of steel wire.

- Nail cutter. The nail cutter is designed to cut the cold drawn wire into wire nails. Due to the high speed and powerful cutting process in the nail making machine, the knives are subject to severe wear and tear. The lifetime is 1-2 months.

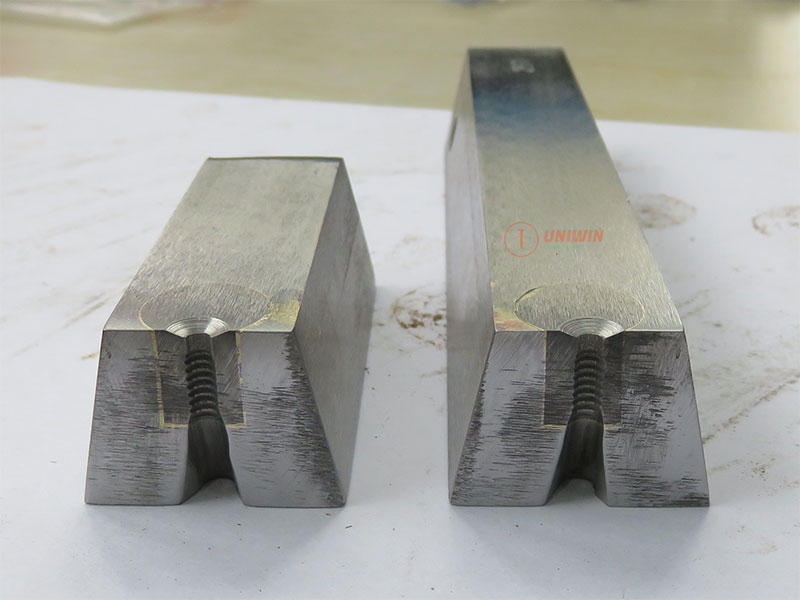

- Nail mold. Also, the nail mold is to grip the wire when punching during the nail making process. The constant operation causes wear and it requires periodic replacement. The lifespan is 3 months.

- Punch bar. The punch bar forms the nail head and needs to be durable and precise. Repeated impacts during the nail forming can cause these components to degrade and require prompt replacement. The lifetime is 6 months.

Maintaining these wearing parts is critical to efficiently operating the wire nail production line. We need to pay attention to the running status of these parts to ensure the quality of wire nails and keep production lines running at optimum capacity.