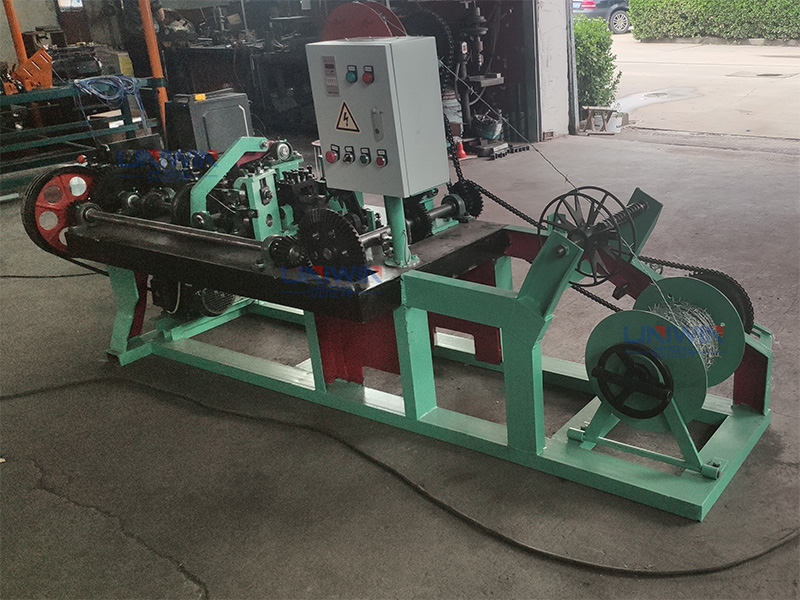

1-6 Inch Automatic Nail Making Machine Nail Manufacturing Machine, Best Selling in Africa

1-6 inch automatic nail making machine is designed to make 1-6 inch wire nails(common nails), coil nails, D type nails, clout nails, concrete nails, etc. We offer turn-key project for nail making plant.

The wire nail has a head and a shank integral with the head, the shank being formed with a tip and having an axis, and the head having a circumferential edge defining a complete circle, characterized in that the center of the head is radially offset from the axis of the shank.

How Much Does a Z94 Nail Making Machine Cost?

The price of a Z94 nail making machine mainly depends on its model, production speed, and automation level. The factory price typically ranges from USD 2,000 to 7,000 per set.

We also provide complete nail production line solutions, including wire drawing machines, nail making machines, nail polishing machines, and packaging equipment.

If you need a detailed quotation for your plant, our team can provide full machine specifications and pricing based on your nail sizes and output requirements.

Z94-C Series Common Nail Making Machine Parameters

| Model | Z94-5C | Z94-4C | Z94-3C | Z94-2C | Z94-1C |

|---|---|---|---|---|---|

| Diameter (mm) | 3.5-6 | 2.8-4.8 | 1.8-3.4 | 1.2-2.8 | 0.9-2.0 |

| Length (mm) | 100-180 | 50-100 | 30-76 | 16-50 | 9-30 |

| Speed (pcs/min) | 220 | 260 | 320 | 340 | 450 |

| Motor power (kw) | 5.5 | 4 | 3 | 3 | 1.5 |

| LxWxH (m) | 2.6×1.7×1.6 | 2.3×1.5×1.4 | 1.9×1.4×1.3 | 1.7×1.3×1.4 | 1.3×1.2×1.1 |

| Weight (kg) | 2200 | 2000 | 1500 | 900 | 450 |

Watch the Z94 Nail Making Machine Working

See how our Z94 Series nail making machine forms nails — from wire feeding and cutting to head shaping and final output.

The machine runs smoothly and produces uniform, sharp nails with high efficiency.

Z94-C Series Nail Machine for Making Nails is Our New Designed Product with the Advantages

- Very low noise: the noise will not make people feel uncomfortable.

- Auto lubrication: Add the lubricant into the small oil tank, and the machine can lubricate the parts automatically.

- Bearing structure and longer lifetime.

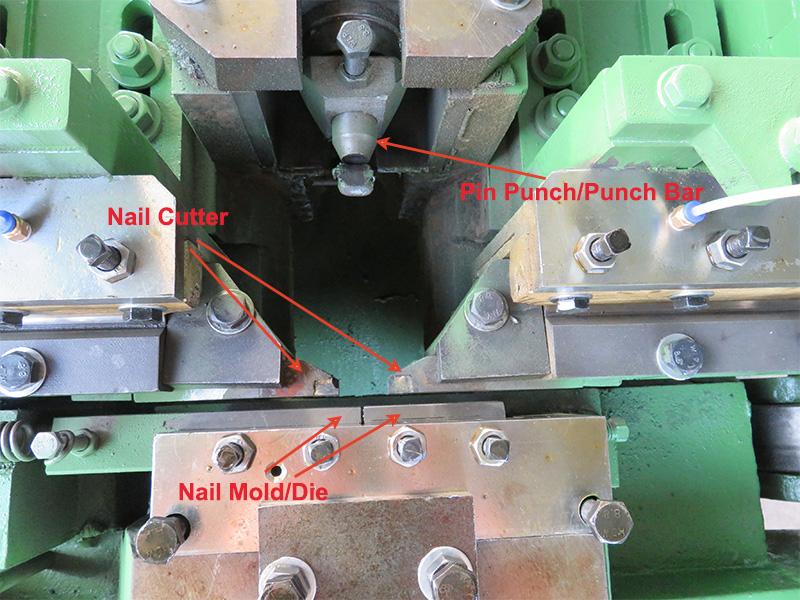

Common Wire Nail Making Machine Spare Parts

- Nail Cutter: Cut the steel wire into different lengths and make nail points, such as 30mm, 45mm, etc. Nail length can be adjusted from 5-150 mm.

- Nail Mould/Nail Die: Clamp/hold the steel wire for the nail cutter to cut.

- Pin Punch/Punch Bar: Make nail head.

The Nail Production Line to Make Common Nails Includes:

- Wire Drawing Machine: Draw the raw material steel wire Q195 or Q235 with a diameter of 6.5 mm to the needed diameter for nails, for example, a diameter of 3.5 mm,3.0 mm, etc., for nails of different lengths. The principle of wire drawing machines is that using different sizes of drawing dies. For example, to draw 6.5 mm steel wire to 5.8 mm, we can use a drawing die of 5.8mm.

- Common Nail-Making Machine: Cut the steel wire into nails and make nail head.

- Nail Polishing Machine: When the nails come out from the nail-making machine, they are not so smooth and bright and need to be polished to make them bright and have a good selling appearance. Concerning the polishing steps, firstly put the nails in the polishing drum, then put some saw dust onto the nails, then cover it and start the machine. In general, it needs 2-3 hours to polish.

These three machines are the main machines to make common nails. Besides these three machines, there are some small machines:

- Sharpening Mill: To sharpen the head of the steel wire before fed into the wire drawing machine. For example, to draw a steel wire of 6.5 mm to 5.8 mm, you need to sharpen the head of the 6.5mm steel wire to less than 5.8 mm first before putting the head into the drawing die.

- Nail Cutter Grinder: Grind the nail cutter to make it sharp again because, after 1-2 days of cutting, the nail cutter installed on the wire nail-making machine will become blunt.

- Butt Welding Machine: To weld the broken wire together and continue the drawing in case the wire breaks during drawing. Without this machine, you must sharpen the wire head again and do everything from the start.

Q195 (SAE1008), Q235 Raw Material Steel Wire to Make Nails:

Good Quality Wire Reel Wire Stand for Nail Making Machines

Finished Wire Nails

Nail Making Machinery and Wire Drawing Machines with Speed Control (By Using Frequency Converter) in Customer’s Factory

Wire Nail Making Machine FAQ

Q1: Is wire nail making profitable?

Yes. The profit margin for wire nails is around USD 50 per ton, so a small factory with 3 tons of daily output can earn about USD 150 per day.

It is one of the most profitable small-scale metal processing businesses.

Q2: What type of steel wire is used for making nails?

The main raw material is SAE1008 / Q195 low-carbon steel wire rod or cold-drawn wire.

For concrete nails, high-carbon steel wire is required to achieve higher hardness and strength.

Q3: Why doesn’t Uniwin sell second-hand nail making machines?

Used nail making machines often have unstable performance and inconsistent spare parts, making maintenance difficult and production efficiency lower.

Although second-hand machines may seem cheaper, their long-term operating costs are much higher.

We only supply brand-new Z94 series and high-speed nail making machines with reliable after-sales service.

Q4: What’s the nail making machine price on Alibaba?

On Alibaba, there are many nail machine suppliers and the price ranges from USD 2,000 to 10,000 per set.

However, most of them are trading companies without technical or after-sales support.

Buying directly from a manufacturer like Uniwin Machinery ensures stable quality, quick response, and genuine spare parts.

Q5: How many nails are there in one kilo?

It depends on nail size:

2-inch nails → approx. 414 pcs/kg

3-inch nails → approx. 148 pcs/kg

4-inch nails → approx. 80 pcs/kg

Q6: Can you export to India, Africa, or South America?

Yes, we have exported Z94 nail making machines to India, Kenya, Tanzania, Ghana, and more than 60 countries with full export documents.

Knowing this helps you calculate material consumption and production cost for your nail factory.

Customer Cases of Z94 Nail Making Machine

Our Z94 Series nail making machines have been successfully installed in India, Kenya, Ghana, Tanzania, Ethiopia, South Africa, Uganda, and Nigeria.

Customers report smooth operation, low noise, and stable nail production quality — even under long working hours.

These successful projects show how Uniwin Machinery helps factories around the world start profitable nail production with low investment.

Get the Best Price for Your Nail Making Project

Whether you are starting a small workshop or expanding an existing nail factory, Uniwin Machinery offers reliable and cost-effective Z94 Series nail making machines for manufacturing 1-6 inch wire nails.

Tell us your nail sizes and daily output, and we will send you a factory quotation and full production plan within 24 hours.

Fast response, original spare parts, and long-term support guaranteed!